our location

Flat No. 101, Imperial Building, 12-2-709/c/207, Padmanabha Nagar Colony, Mehdipatnam, Hyderabad - 500 028.

Mail Us

samki@samkigroup.in

Complete solutions for Recycling Plastics and Solid waste management.

SAMKI Group of Companies

SAMKI GROUP is managed by a group of experienced technocrats from engineering background. We focus primarily on Recycling Plastics and Solid waste management.

With in-depth understanding of technology, markets, management structures, raw materials, manpower requirements and the latest technologies available over the world, we offer you customized solutions.

Samkitec Green Technologies is in the field of Plastic Recycling for more than 17 years. We were the first to introduce PET Bottle and CD/DVD recycling in this country.

S. Sampath

President & Chief Executive

+

years of experience

We Offer

Municipal Solid Waste Management

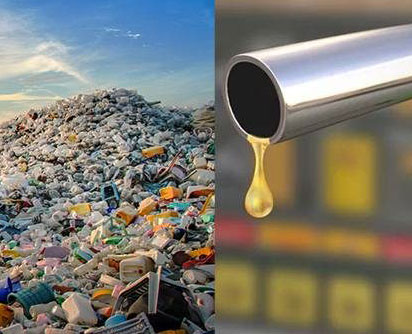

Pyrolysis

Torrefaction

Rdf to Leaf

Waste to energy solutions

Biogas –Organic and Food Waste segregated from MSW

PET Bottle Recycling

PET Bottle Recycling

“They were fantastic through the entire purchase process. Had lots of questions and they were patient. When my system arrived, it was well packed and shipping done smoothly with Samki group.”

“They helped lead me through the process of system selection, site layout and placing my order. They were very knowledgeable and has provided guidance each step.”

“They helped lead me through the process of system selection, site layout and placing my order. They were very knowledgeable and has provided guidance each step.”

Latest News

The task force headed by K Kasturirangan has proposed a target of setting up 215 Waste to Energy plants by 2031 to generate 1,075 MW of power and has strongly pitched for setting these up through public-private partnerships (PPPs) with viability gap funding of up to 40 per cent.

The fundamental problem of this country is segregation of the municipal solid waste. Segregation & sourcing (by the people may not give a complete solution). The best way is to provide Automatic segregation system with an apparel technology such as BMH Technology Oy - Finland

Pyrogreen Private Limited brings this Unique and Cost Effective Technology to extract Fuel from Waste Plastics. It is a completely automatic plant equipped with all control & safety features.

This technology called the Thermophilic Digestion System is the fastest process so far in organic waste treatment industry. It work at thermophilic phase and break down complex organic compounds into simpler organic matter at an exceptional speed.

Nowaste is an eco-friendly and economic solution for solid waste disposal which runs on the principle of incineration but with no input energy.